BIOFILTER RAISED FLOORING SYSTEM

High-quality exhaust air cleaning

The chemical-resistant solution

YOUR ADVANTAGES AT A GLANCE

Material characteristics of hanit

High load bearing capacity

Resistant to acids, alkalis and oils

Hydrophobic

UV-resistant

Continuous operating temperature of -20 to 50 °C

Resistant to micro-organisms

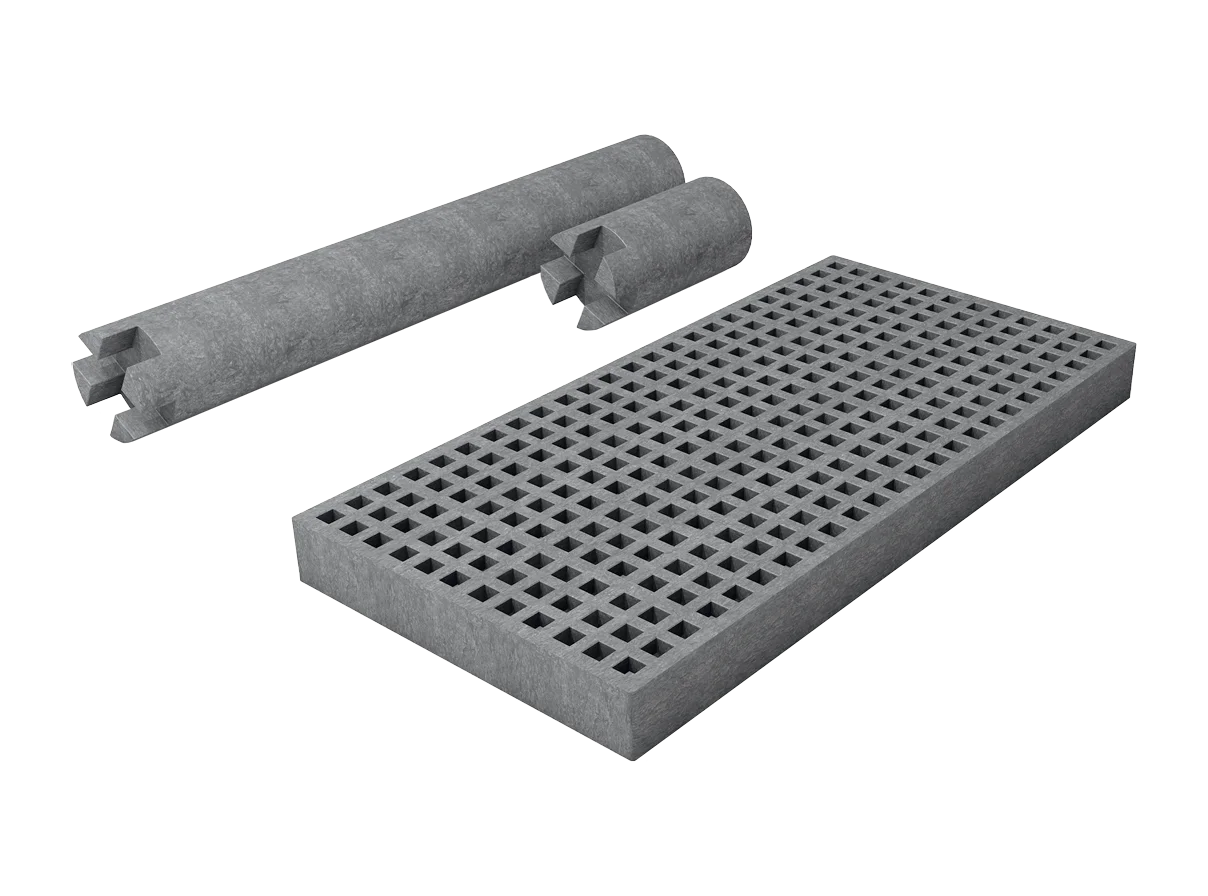

BIOFILTER RAISED FLOORING SYSTEM MADE FROM RECYCLING PLASTIC

Individual solutions from hanit

Our hanit System products can be flexibly adapted to customer-specific requirements. Just talk to us – we’ll find the right solution together.

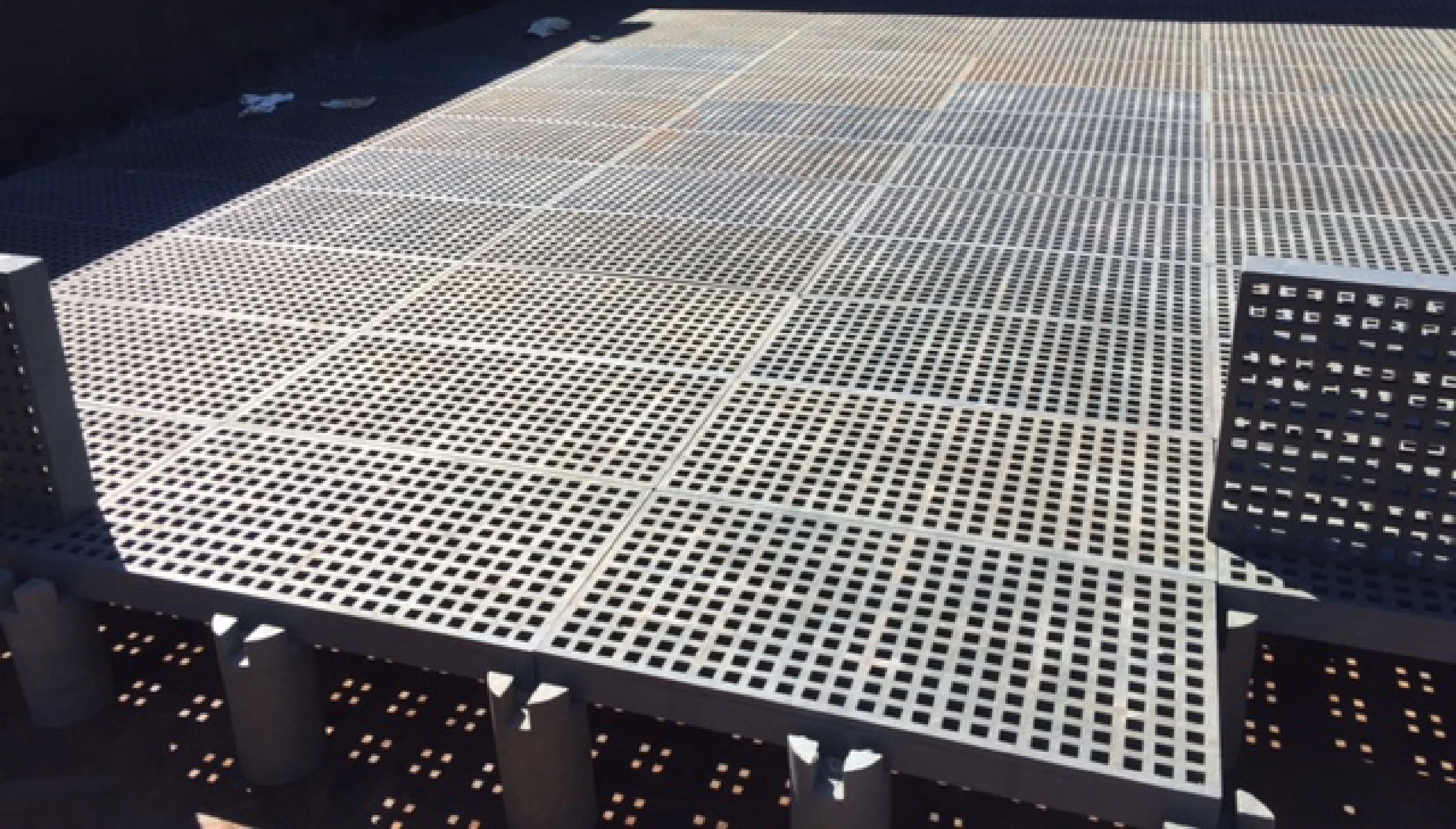

REFERENCE PROJECT

Melbourne Water | Sewage treatment plant east | Melbourne Australia

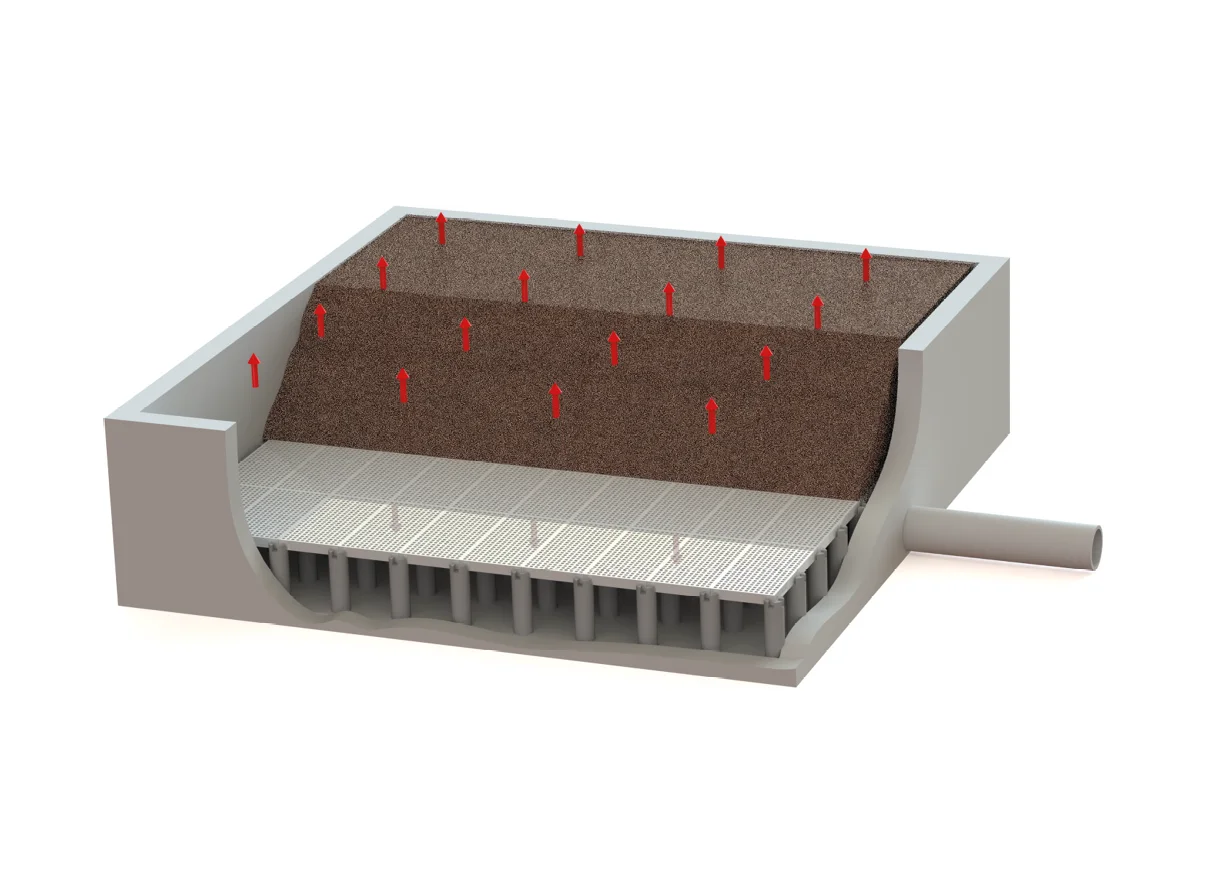

The bio-filter had to be replaced in 2017 because of extreme wear. As part of a tender, Bioaction, a specialised service provider for wastewater customers in the area of odour prevention and corrosion reduction, was granted the order for redevelopment. Shortly afterwards the company approached us to discuss the possibility of using hanit recycling plastic and involving HAHN Plastics in the project as a technically experienced partner. In addition to a significant amount of wear, other problems were also discovered during the initial assessment on-site. It quickly became clear that the original construction had several deficits, including a significantly elevated bio-filter floor. Another challenge was the fulfilment of the environmental regulations, which could only be achieved with optimum bio-filter performance. For this reason, Melbourne Water considered extending the system by constructing a new 6-cell bio-filter to increase its capacity.

During the planning phase, Bioaction carried out CFD modelling (Computational Fluid Dynamics) to simulate the use of hanit recycling plastic and the associated advantages thereof. The model showed that a floor structure with hanit would increase the effective surfaces of the media bed and would therefore lead to more even air distribution through the filter media. Following the successful implementation of the project, the hanit floor structure proved to have another significant advantage. The capacity of the bio-filter could be increased by 20 % by using separate support feet with different heights. This meant that the originally planned extension of the system was no longer needed, which saved customer Melbourne Water a considerable amount of money.

The project was completed in June 2017. Overall, the project was able to be implemented to the customer’s complete satisfaction, not only from a timing point of view, but also because of the quick and easy installation, and also financially thanks to the capacity increase.

TECHNICAL DATA

Standard dimensions - special dimensions on request

YOUR CONTACTS

Get in touch

Georgina Bourdon

+44 161 8501965

+44 7961630 886

georgina.bourdon@hahnplastics.co.uk

Our technical sales experts are also active on LinkedIn. Would you like to keep up to date on the topic of supply ducts or exchange ideas with our experts on this topic? Network now and never miss any news again.

Would you like to receive more information about this product or make an appointment for a consultation? Then simply use our contact form. Our experts will usually get back to you within 24 hours on weekdays.