TUNNEL BLOCKS

Practical support for tunnel construction

Durable and dimensionally stable

YOUR ADVANTAGES AT A GLANCE

Material characteristics of hanit

High load bearing capacity

Hydrophobic

UV-resistant

Fire class B2 (DIN 4102)

Density of approx. 0.93 g/cm3

Testing of mechanical parameters available

TUNNEL BLOCKS MADE FROM RECYCLING PLASTIC

Individual solutions from hanit

Our hanit System products can be flexibly adapted to customer-specific requirements. Just talk to us – we’ll find the right solution together.

REFERENCE PROJECT

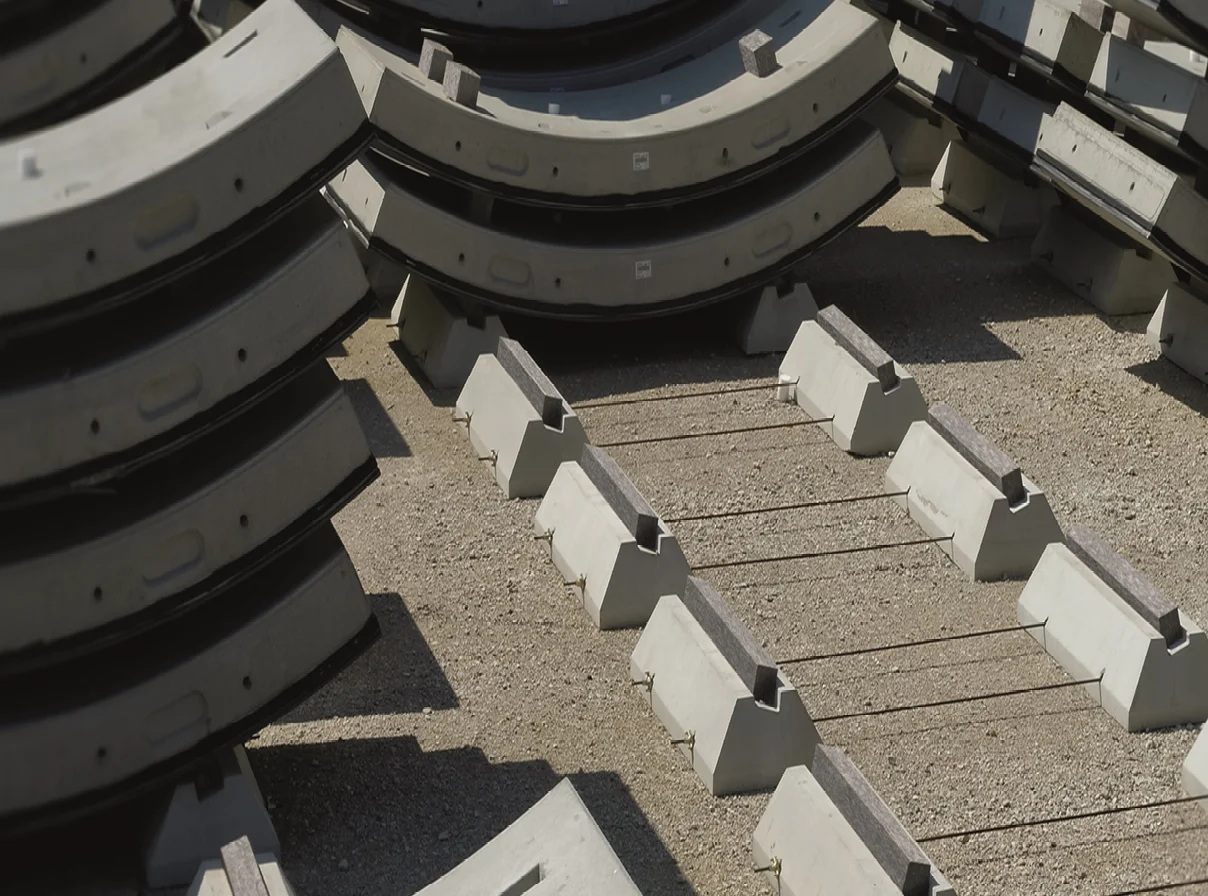

SCS JV | HS2 high-speed railway | United Kingdom

Around 105 kilometres of tunnel will be built between London and West Midlands for the project, for which 130 million tonnes of earth needs excavating. Ten tunnel boring machines in five separate tunnel drives will dig the twin-bore HS2 tunnels. A further six cut and cover tunnels will be built, with trees and shrubs planted on top to improve the landscape. The project is in two parts, the planning phase, with a contract value of approx. GBP 79 million, and the realisation phase, with a construction volume of approx. GBP 2 billion.

STRABAG SE, a European-based technology group, won the contract for the main construction of lots S1 and S2 for this enormous infrastructure project. STRABAG is active in all areas of the construction industry with extensive expertise in planning and building high-speed railways. STRABAG is teaming up with Skanska and Costain to build the HS2 under the joint venture SCS. The first construction works will connect London Euston and Old Oak Common railway stations. This stage involves constructing an 8.8 km twin-bore tunnel. The second stage will connect Old Oak Common in the west with a 13.7 km twin-bore tunnel as well as a 2.2 km above-ground segment.

Over the past few years, STRABAG has already used our hanit tunnel blocks in many of its tunnel projects to store segments without placing them under stress and to transport them safely. Sections weighing up to 65 tonnes were stacked in the massive HS2 project, and our blocks met the challenge because the stable supports made of recycled plastic can easily withstand loads of up to 3 N/mm². A total of 36,000 tunnel blocks were used during the construction of the first twin-bore tunnel. A further 36,000 hanit tunnel blocks will build the second tunnel.

Work on the first stage of the high-speed railway was completed on schedule at the end of 2022. The upcoming 18 to 24 months will focus on planning and delivering the rail systems, signalling equipment, tracks and the electricity supply. The first trains are due to start using the tracks from 2030. Work on the second stage begins in 2023 and is expected to be completed between 2035 and 2040.

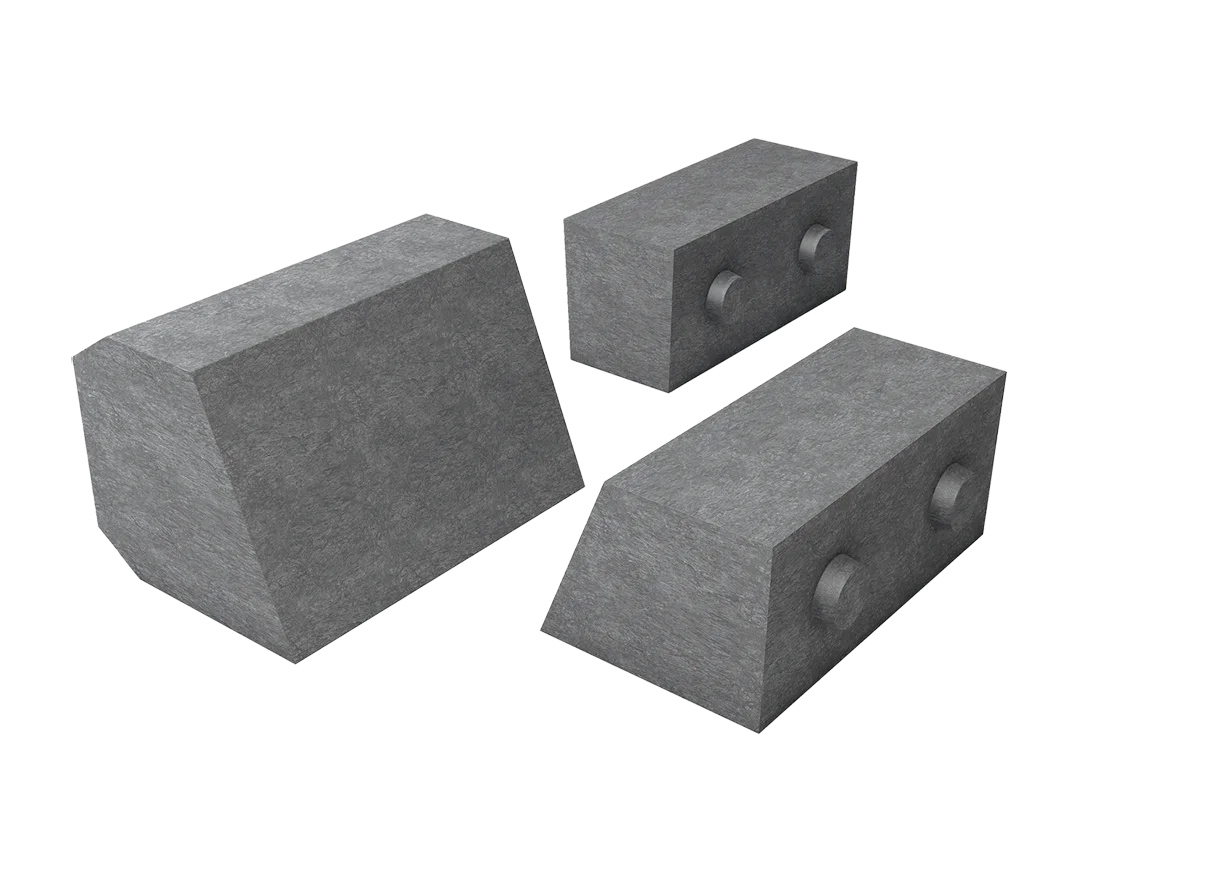

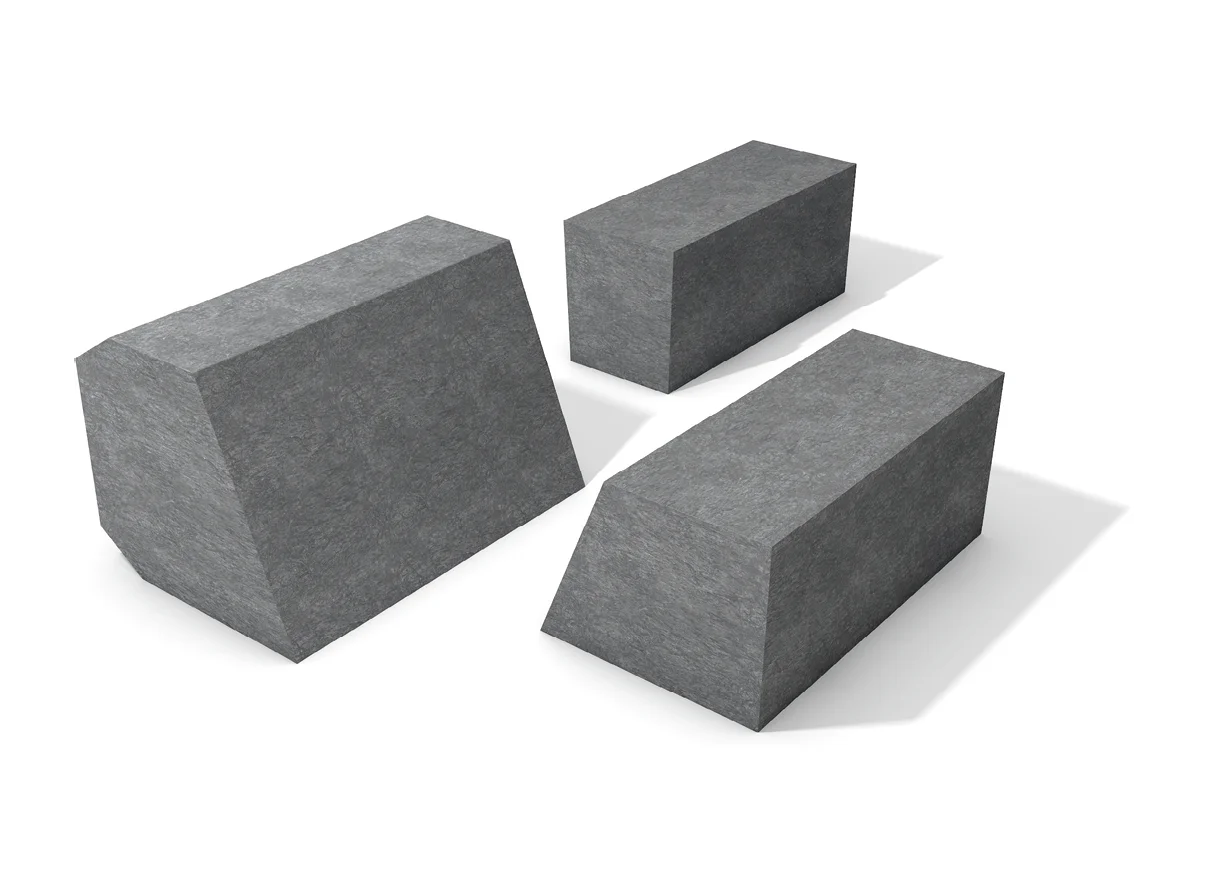

TECHNICAL DATA

Project-specific dimensions

Radius, locking knobs, recessed grips or markings can also be realized very easily.

YOUR CONTACTS

Get in touch

Georgina Bourdon

+44 161 8501965

+44 7961630 886

georgina.bourdon@hahnplastics.co.uk

Our technical sales experts are also active on LinkedIn. Would you like to keep up to date on the topic of supply ducts or exchange ideas with our experts on this topic? Network now and never miss any news again.

Would you like to receive more information about this product or make an appointment for a consultation? Then simply use our contact form. Our experts will usually get back to you within 24 hours on weekdays.